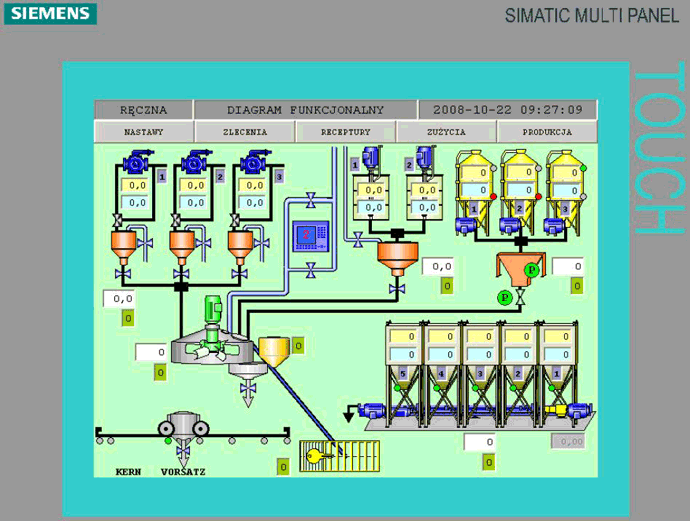

The complete control system SYSBET II

"In 2008 our company has implemented two optimizing solutions into our Sysbet II control system which have been since qualified by the experts from Technical University in Poznan as TECHNICAL INNOVATIONS (fulfilling the standards taken under consideration during the investment award financing programme by the European Union)."

The SYSBET II control system fulfills the requirements of the EU norm PN-EN 206-1:2003 which is obligatory for all producers of ready mix concrete.

Customers using our software can also produce other kinds of concrete mixes, depending on the configuration of theirs plant.

Our very well tested and reliable software guarantees:

- dosing of aggregates with an accuracy of 1%, and other ingredients with an accuracy of 0.5%; in case of a cement dosing it is +/- 1kg. The effect: high quality and repeatability of production and also cement savings!!!

- ensuring registration of production and issue of the documents in accordance with the norm EN 206-1

- fulfilling the requirements of the norm EN 45501, for the calibration of the weighing devices,

- repeatability of the concrete in every mix,

- cement savings and doubled REGISTRATION OF ITS CONSUMPTION in purpose of REGISTRATION OF ITS NON-NORMATIVE CONSUMPTION,

- fulfilling the technological requirements of certain concrete class,

- repeatability of the concrete regardless of aggregate moisture level,

- minimalisation of human mistakes,

- full record and control of production with an export of data to an external filing computer.

- hidden from the operator registration of events essential for the cement consumption as well as the amount and kind of produced concrete.

Wide and practical desk type control panel is equipped with:

big, colour, touchscreen SIEMENS panel for visualization and adjusting of the process parameters,

big, colour, touchscreen SIEMENS panel for visualization and adjusting of the process parameters,- programmable SIEMENS controller type S7-300 or S7-200,

- digital weights terminals in compliance to the norm PN-EN 206-1:2003,

- voltmeter, phases control sensor,

- analog measurement of mixer's drive load - additional control of mixture's consistence, CONVENIENT GRAPHIC DIAGRAM,

- main switch, engine switches and contactors for the mains power circuits, power supply 3x400V+N+PE, 50Hz

- separate specialized safety circuit (certified safety contactor)

- relays and safety devices securing control circuits.

Electrical documentation:

- Functional lay-out of the batching plant

- Electrical blueprints of supplied cabinets,

- Declaration of compatibility with EU norms,

- User's manual of control system,

- Protocols from electric measurements.

The automatic control system SYSBET II - automatic control of the batching plant with a programmable Siemens controller. The big control panel MP277B, used for control, is equipped with 10,4" color touch-screen. The control system works on MARPO software. It allows for a full parameterisation of ingredients weighing process, shortening of mixing cycle's length by emptying the mixer based on current load measurement, and setting a new order during while the previous one is still being processed. The plant operator is informed about the errors of system's performance with an alarm messages shown on the screen.

Main features of SYSBET II software:

Coarse or fine dosing (aggregates, cement, water, chemical additives, colours)

the parameters of each material's dosing can be modified by the operator due to current needs. These changes are immediately implemented by the control system and there's no need to wait for the effects to the next mixing cycle.

Complete control of each weight status

Possibility of configuration of parameters for every scales, such as: emptying tolerance, time and break of emptying, minimal and maximal feeding time or emptying time.

Mixer's feeding order

Sequence of materials' filling into the mixer, beginning with feeding of the aggregates, can be freely configured

Aggregate's moisture compensation

System can be configured to perform measurement of each aggregate's moisture

Moisture measurement in mixer

System has the interface for the mixer's moisture probe Ludwig or Hydronix

Configuration of the access to the system with passwords

All data and functions pointed out by the factory management can be protected by supervisor code (password).

The record of consumption data

System records daily consumption of materials and total amounts produced in automatic mode of work, furthermore these data can be displayed and printed for the certain (chosen by the user) period.

Record of the production cycle

All data concerned with the production cycle done in the automatic mode of work are recorded.

Simplicity of use

Thanks to maximum work's simplification the system can be operated by the lower qualified personnel

Managing of production processes

Possibility of interrupting, resuming and canceling all the running processes.

Managing of production orders

It is possible to enter simultaneously two production orders

Managing of recipes - recipes memory

Possibility of entering and recording over than 100 mix recipes.

Managing of alarms

System keeps in the memory lists of alarms which have occurred, the list can be displayed and printed.

Monitoring of each material's consumption

System based on data entered from the delivery documents, informs about the need of filling the cement silos.

Module of supervision for the batching plant parameters

Facility for the factory management

The external filing computer (optional)

The external filing computer is equipped with a separate database of clients, vehicles, and registration of construction sites, schedule, as well as address book with the mode of printing and keeping delivery documents in memory.